Collapsible content

Technical Datasheets

Shipping

Shipping rates and delivery times are calculated at checkout.

Manufacturing lead time is dependant on quantity ordered. This is excluding the delivery lead time which is estimated at checkout.

We aim to process and get your delivery with you as quick as possible.

Please contact us to retrieve the estimate lead times for your order.

Guarantee

We aim to provide you with the best quality products, if for an unfortunate product defect we have a 14 day money back return guarantee.

Warranty

• 1 year warranty from the date of purchase.

• Invoice or shipment bill is required to claim the warranty.

• The warranty policy only requires manufacturer to repair the defective product or send substitute for replacement.

• Installation labour, electricity cost and other related cost will not be covered by the manufacturer warranty policy.

• Warranty doesn't cover the defect caused by inappropriate use, especially if directions of the instructions for use are not observed, normal abrasion as well as failures which affect the value or use of the product insignificantly.

Please see our returns policy for more information.

-

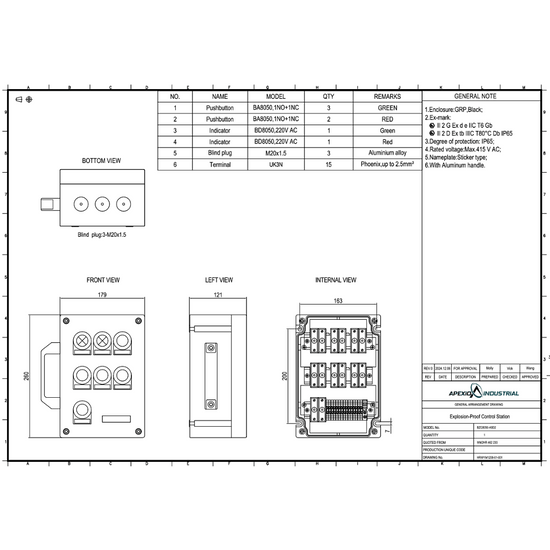

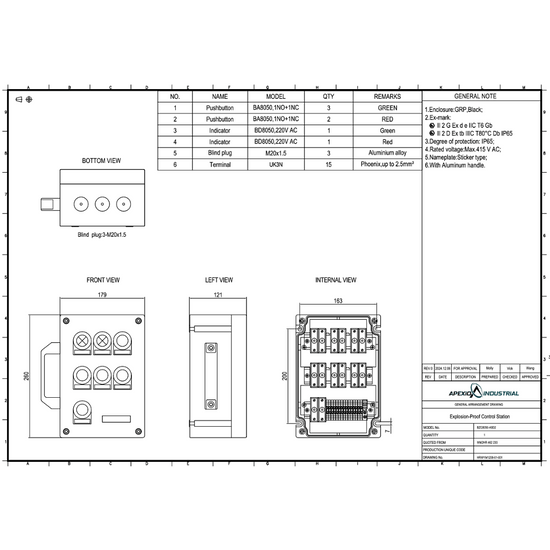

Hazardous Area Certified

Certification

- IECEx DNV 21.0047X

Equipment Protection Level

IECEx

With optical fibre:

Ex db op pr IIC T6 Gb

Ex tb op pr IIIC T80°C Db

Without optical fibre:

Ex db IIC T6 Gb

Ex tb IIIC T80°C DbATEX

Without optical fibre

II 2 G Ex db IIC T6 Gb

II 2 D Ex tb IIIC T80°C Db

With optical fibre

II 2 G Ex db op pr IIC T6 Gb

II 2 D Ex tb op pr IIIC T80°C Db -

Key Features:

• ATEX, IECEx certified

• Application: gas zone 1, zone 2; dust zone 21, 22. • Exd II CT6 Gb/ Ex tD A21 IP68 T80℃

• Stainless steel 304 or 316L

• Optional electropolished or corrosion resistant paint finish

• Enclosure Protection: IP66, IP68 (2m, 2h) • Power input: DC12V/1.5A or POE power supply

• 1/3” 4Megapixel CMOS

• Powerful 4x optical zoom

• Max. 25/30fps@4M/3M

• ROI, H.264+/H.265+

• WDR, Day/Night(ICR), Ultra DNR

• Intelligent detection: Intrusion, tripwire -

Options

Option of fill light

Blank: without fill light

F: with fill light

Option of configuration or optical fibre:Blank: High configurationA: Basic configuration

B: Lower configuration

C: Optical fibre network

D: Straight configuration

Applications

-

Oil & Gas Facilities

Onshore and offshore oil rigs

Gas processing plants

Refining units

LNG terminals

How it's used:

It is used to continuously monitor critical processes, detect leaks, oversee hot work activities, and provide real-time visual feedback to control rooms — especially in places where personnel cannot be physically present due to safety risks. The camera’s explosion-proof rating ensures no risk of ignition in the event of a gas leak. -

Chemical Processing Plants

Mixing and reaction zones

Solvent storage areas

Gas cylinder rooms

Corrosive material handling sections

How it's used:

Chemical plants deal with volatile materials and often have high humidity, corrosion, or acidic atmospheres. The 316L stainless steel housing and optional electro-polished finish withstand aggressive environments. It enables safe remote surveillance of sensitive areas, allowing for early detection of spills, smoke, or unauthorized access. -

Grain Storage & Handling Facilities

Silos

Conveyor transfer points

Grain dryers

Dust-prone storage areas

How it's used:

In grain processing and storage, fine dust particles pose a significant explosion hazard (Zone 21 and 22). Used to monitor machinery operation, detect overheating equipment, and ensure safe loading/unloading practices. Its built-in defogger and wiper keep visibility clear in dusty atmospheres.

Precision Surveillance

Equipped with a high-performance STARVIS CMOS sensor, it captures full HD video at 60fps, even in low-light conditions as dark as 0.005 Lux. The 30X optical zoom and intelligent pan-tilt mechanism give operators full 360° coverage with fast, smooth transitions and pinpoint accuracy.

Ex CCTV Camera Intro Video

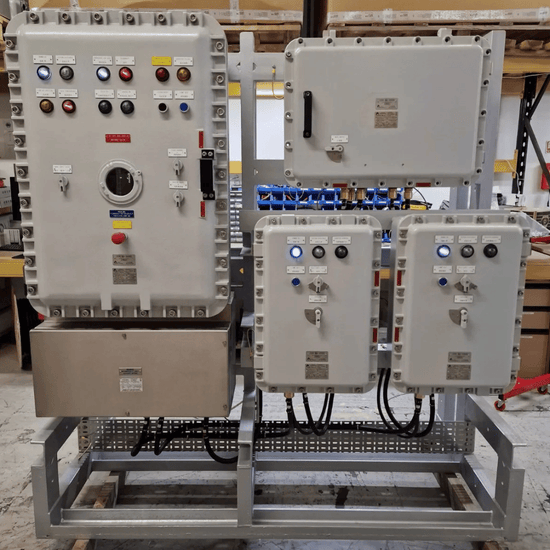

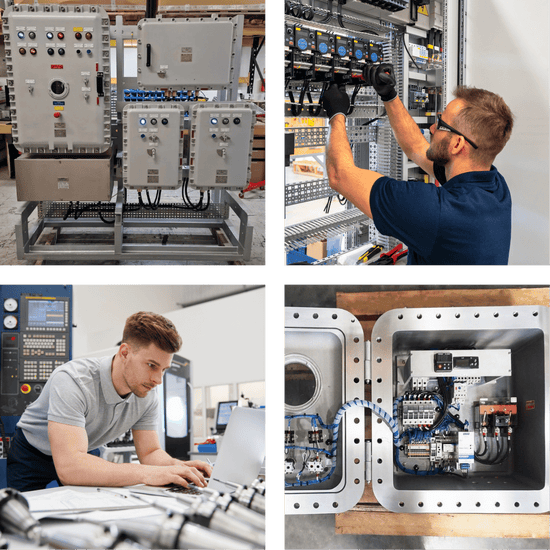

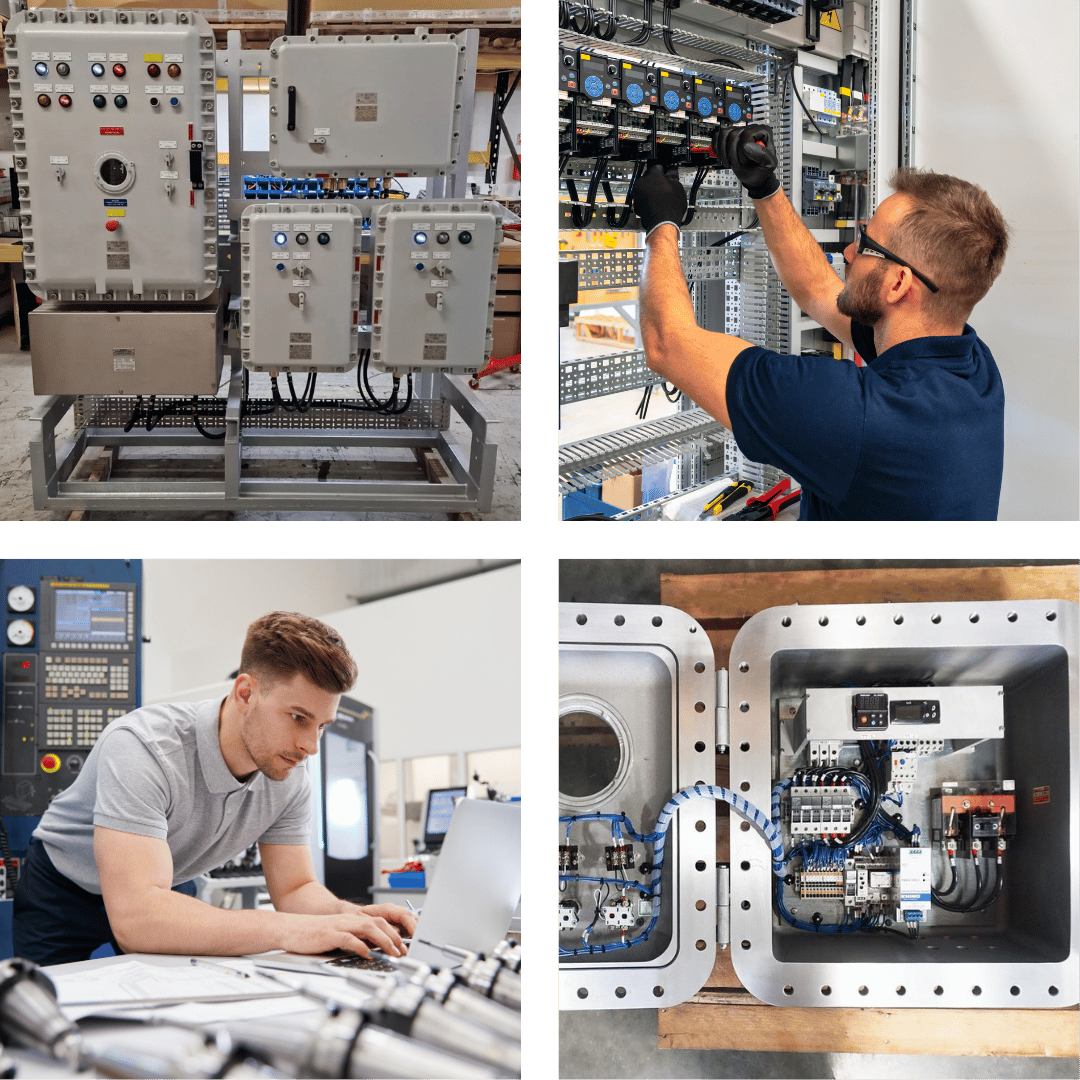

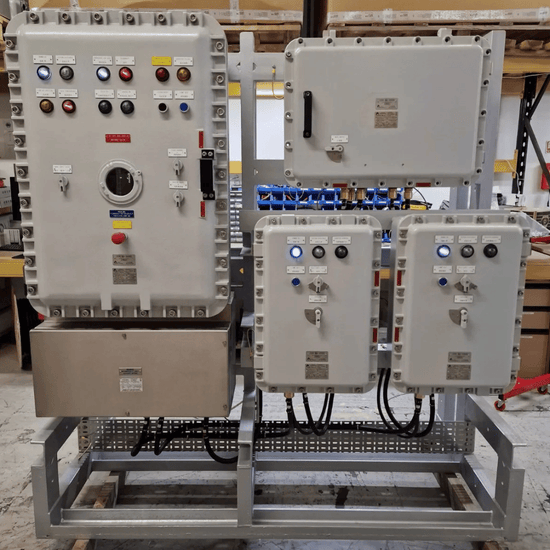

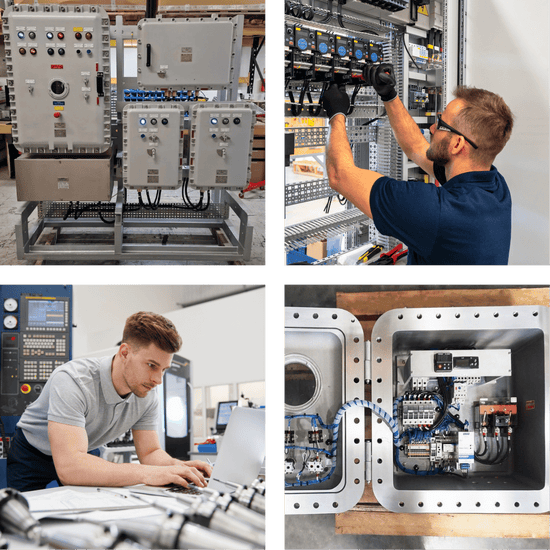

Ex Electrical Manufacturing & Fabrication

We offer after sales support on a wide range of our products including:

- Design & CAD Drawing

- Product and Component Selection

- Bill of materials

- Engineered Fabrication

- Factory Acceptance Testing (FAT)

- Professional packaging and delivery

- Installation

- Calibration

- Maintenance & Repair

Need help with custom ex electrical design and fabrication

-

Design

Utilise our skilful resources with ATEX / IECEx workshop to bring your ex electrical design to life.

-

Fabrication

From pre-approved designs to custom solution ATEX / IECEx control stations, motor starters, distribution panels. We have you covered.

-

Install & Maintain

With full turnkey solutions we have capability to install, commission and maintain your systems.

Pre & Post Sales Support

- We offer technical after sales support to ensure our clients are backed by our team.

- Whether you need support with custom project fabrication, calibration, on-site installation.

- We are here to bring a partnered business relationship with you.

- Our fulfilment warehouse has stocking capabilities for small or large projects.

Contact form

British operated and owned.

Our Core Values

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.